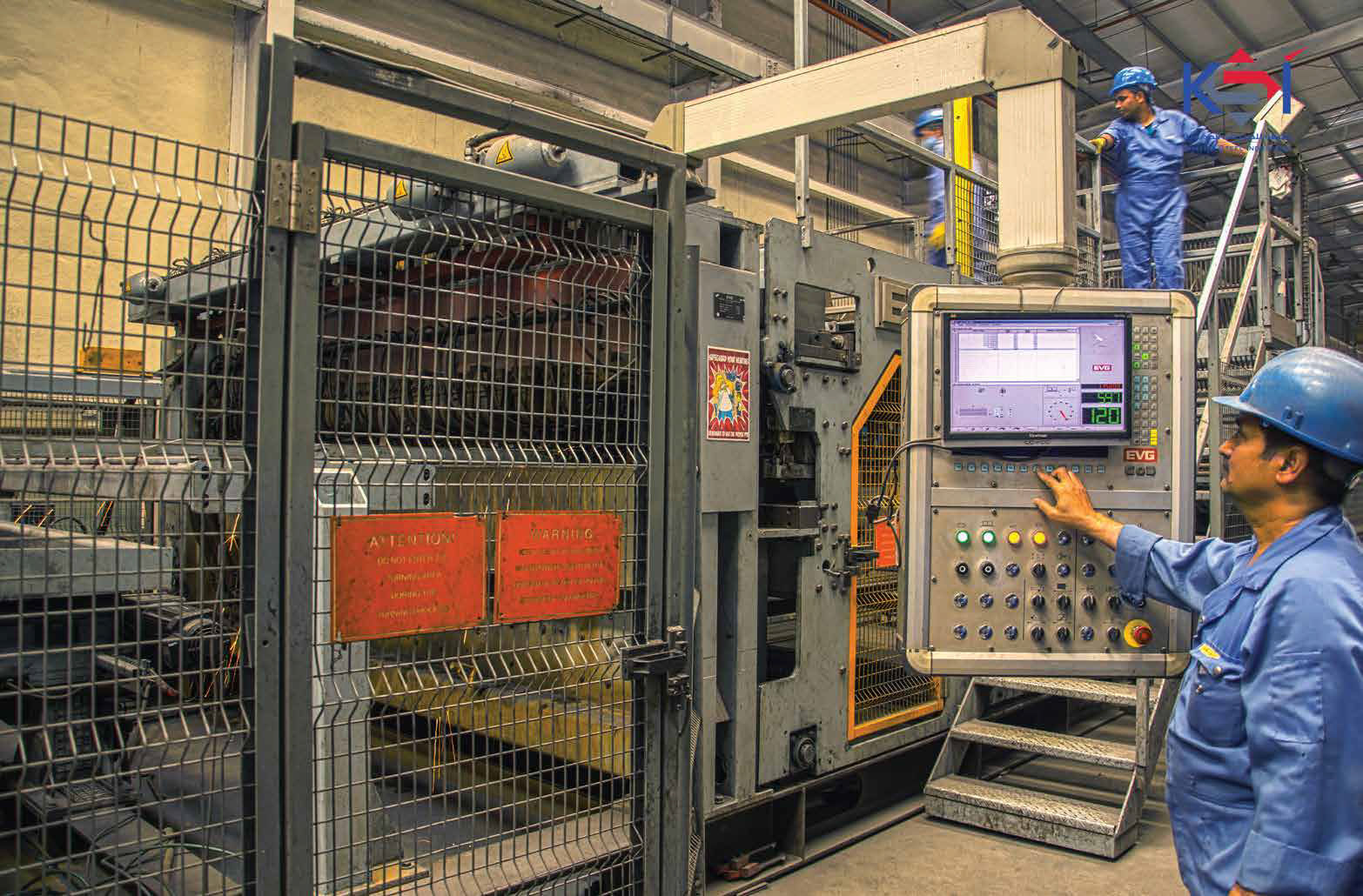

MACHINERIES

Khalifa Steel Industries W.L.L. is equipped with modern machineries of advanced technology for cutting and bending of reinforcing steel, the high capacity and the automation of the machineries results in shorter delivery times and higher accuracy in dimensions. Details of different types of machines as are follows: